Piles

They form the foundation without which countless buildings would be impossible to construct: our bored piles. These are cylindrical bodies made of concrete with or without reinforcement. They discharge high structural loads into load-bearing soil strata and are constructed in a line or with overlapping secant design to form a supporting wall for an excavation pit or to seal off groundwater. The length, diameter, material, formation and placement of the piles can vary according to your individual requirements.

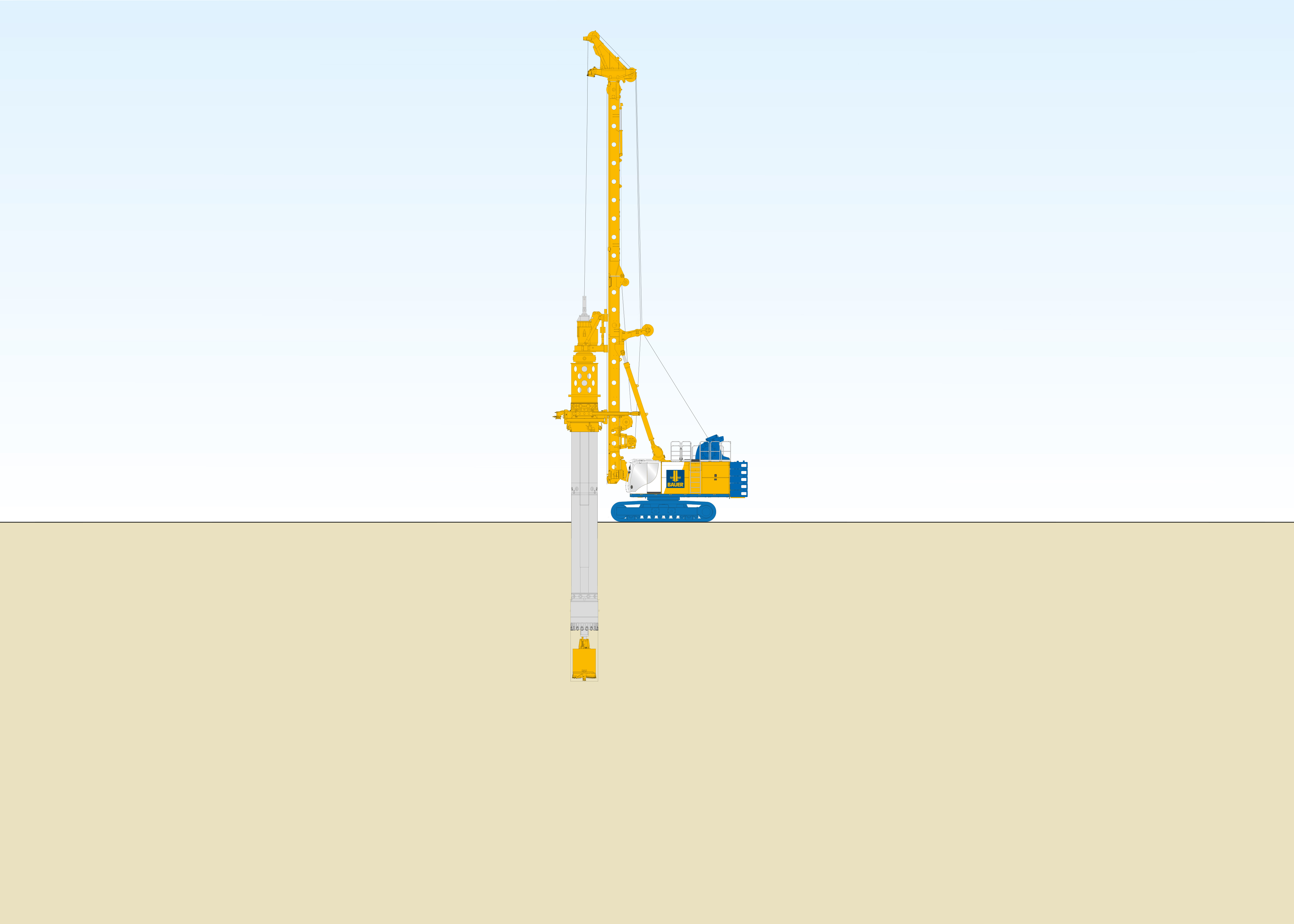

Kelly pile

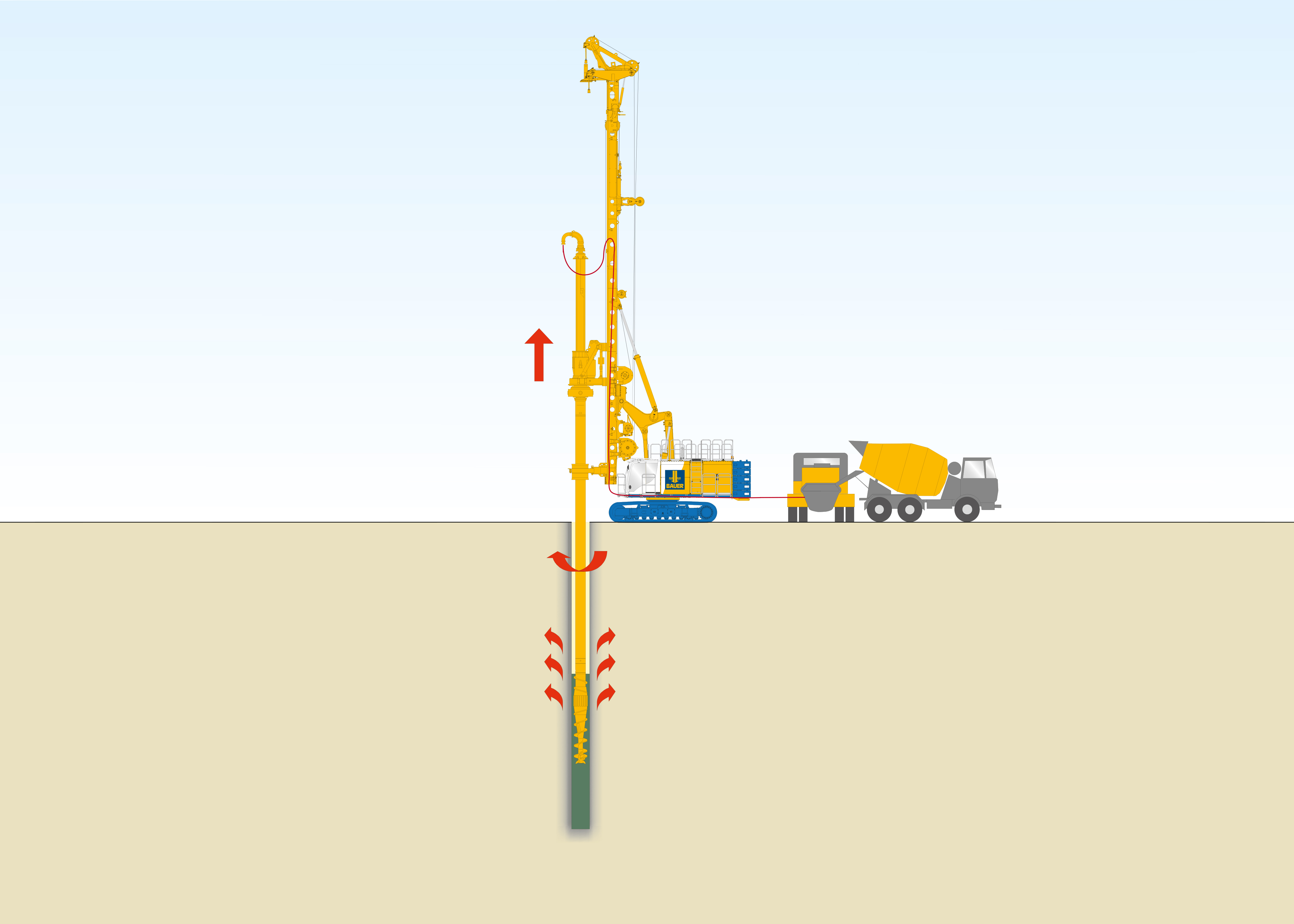

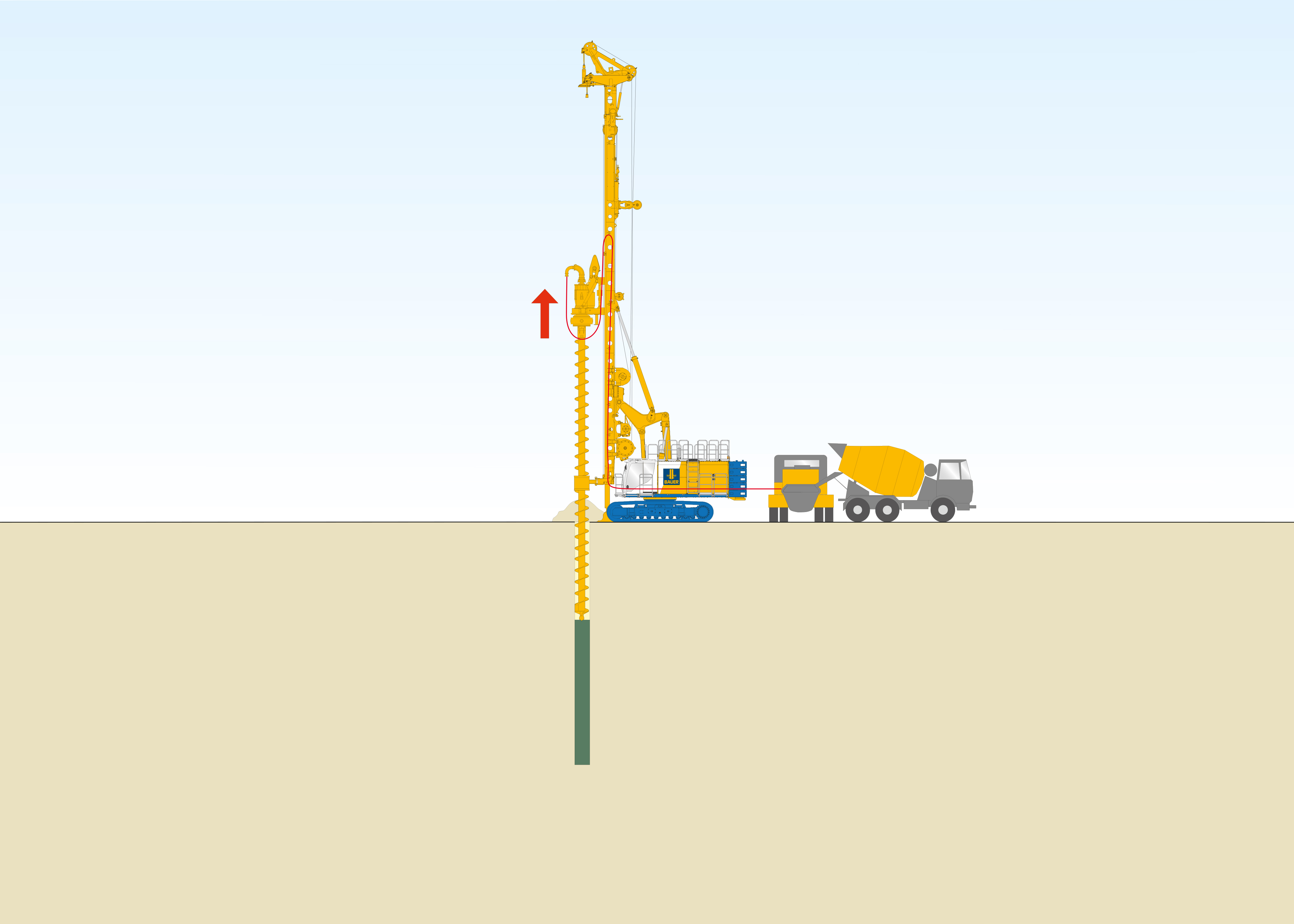

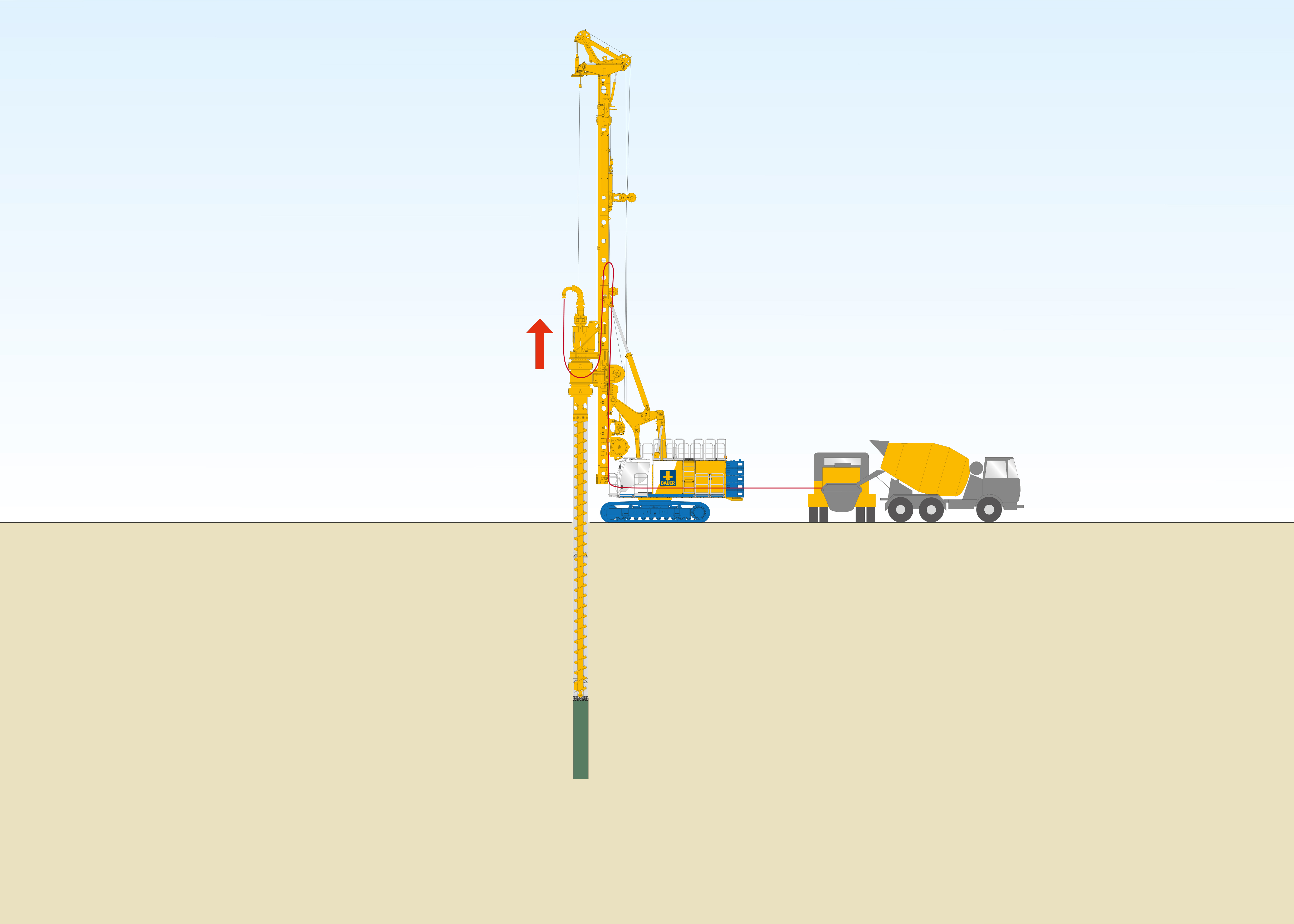

Continuous Flight Auger pile (CFA)

Double-head drilling system (Twin Rotary Head)